clamp on ultrasonic flow meter installation guidelines

VersaFlow Clamp-On Ultrasonic flow meters are designed for applications where a customer is unwilling or unable to cut into the process measurement line to install an in-line meter. With clamp-on ultrasonic flow meters the key to a good installation is making sure that the pipe it is affixed to has acoustical properties that will allow the ultrasonic principle of measurement to function properly.

Clamp On Ultrasonic Flow Meter Xtsensors

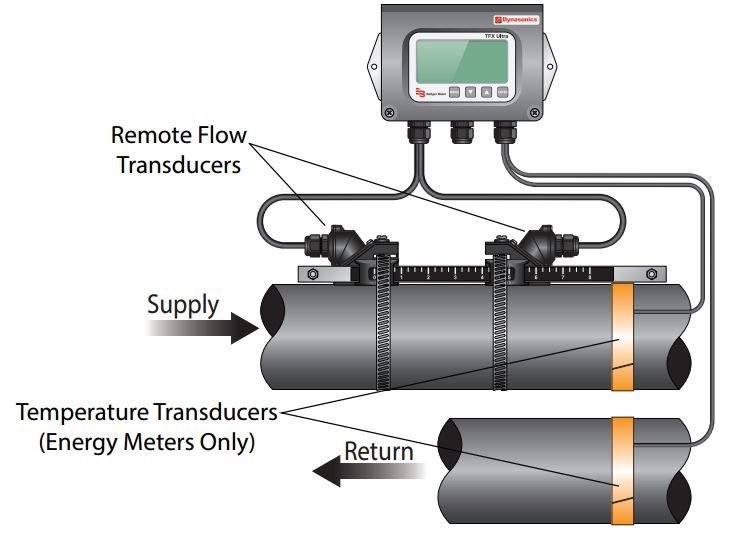

12 TYPICAL FP-4400 FLOW METER INSTALLATION The FP-4400 Portable Clamp-on Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on the outside wall of the pipe.

. The price depends on the type and range of flows that can be measured. They are among the most cost-effective flow measurement technologies for measuring volumetric flow rates of liquids. The Tek-Clamp 1200A operates according to the difference in the Transit Time of Flight measured and determines the flow velocity by measuring the travel time of a pulse from one transducer.

Therefore the selection of its diameter can generally be smaller than the size of the main pipeline which can reduce the overall investment in the straight pipe. The VorTek U42 Commercial Series and U43 Water Series of Ultrasonic Flow Meters. Up to 15 cash back Flow Measurement of Drinking Water Clamp-on Ultrasonic Flow is a non-intrusive technology that is applied to the outside of process piping.

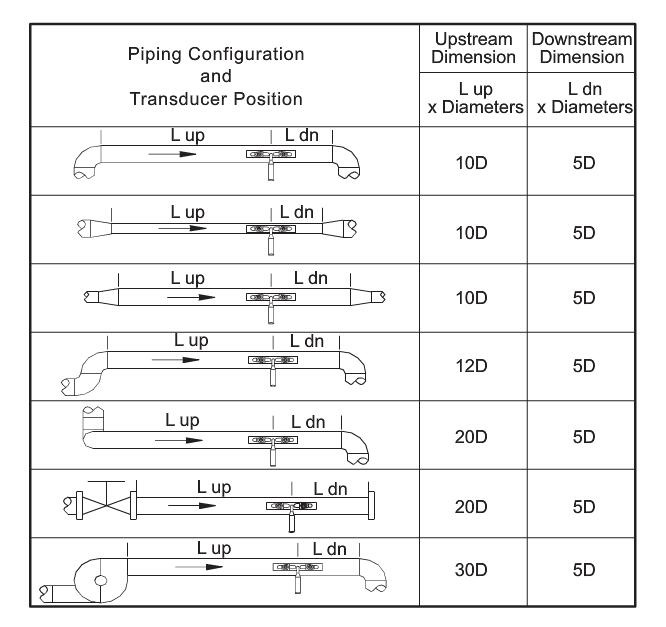

Besides the transducer installation site should be at least 30D away from the pump. It is a measurement system which is both easy to install and use. Please contact the factory for more information.

A clamp-on ultrasonic flow meter consists of at least two ultrasonic sensors mounted externally to a pipe. Repeat the start sequence. Tek-Clamp 1200A Ultrasonic Clamp On Flow Meter is designed to measure the fluid velocity of liquid in a full or closed pipe.

Always refer to your product manual for your exact flow meter. It is suitable for measuring the volumetric flow of liquids in a wide variety of applications including bi-directional flow applications. In the first of our application notes for ultrasonic clamp on meters it is astoundingly clear that meter quality is a significant contributor to attaining accurate flow measurement results.

No pipeline disturbance no pressure loss Suitable for most pipe materials with diameters from 6 mm to 65 m 14 to 256 Process temperatures from -30 to 300 C -22 to 572 F 2 flow and 2 virtual channels standard. This means low install costs. Ideal for clean liquid applications this transit-time measurement technology reduces installation downtime and provides significant cost effectiveness when compared to inline flow measurement equipment.

Clamp-on sensors with no process interruption. Non-invasive flow measurement of liquids. At the time of preparation of this fact sheet the price for a single unit ranged between 2000 and 13000.

VorTek clamp-on ultrasonic flow meters are clamped on to the outside of the pipe and never directly contact the media inside the pipe. Available in configurations for pipe line sizes from DN15 to DN4000 12 to 160 the clamp-on design offers a cost-effective means of measuring. Installation Guidelines for Inline Ultrasonic Flow Meters.

It is suitable for measuring the volumetric flow of liquids in a wide variety of applications including bi-directional flow applications. 13 TYPICAL F-4300 FLOW METER The F-4300 Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on the outside wall of the pipe. Benefits of Clampon Meters The main benefit of a clampon meters is that the pipe does not need to be cut as seen with typical flow meter installations ie.

Producing consistently accurate results with an ultrasonic flow meter depends heavily on a proper installation. With traverse type set-up coupling pastes pipe sizes particulatebubbles pipe. This benefit becomes greater and greater as the pipe size is increased.

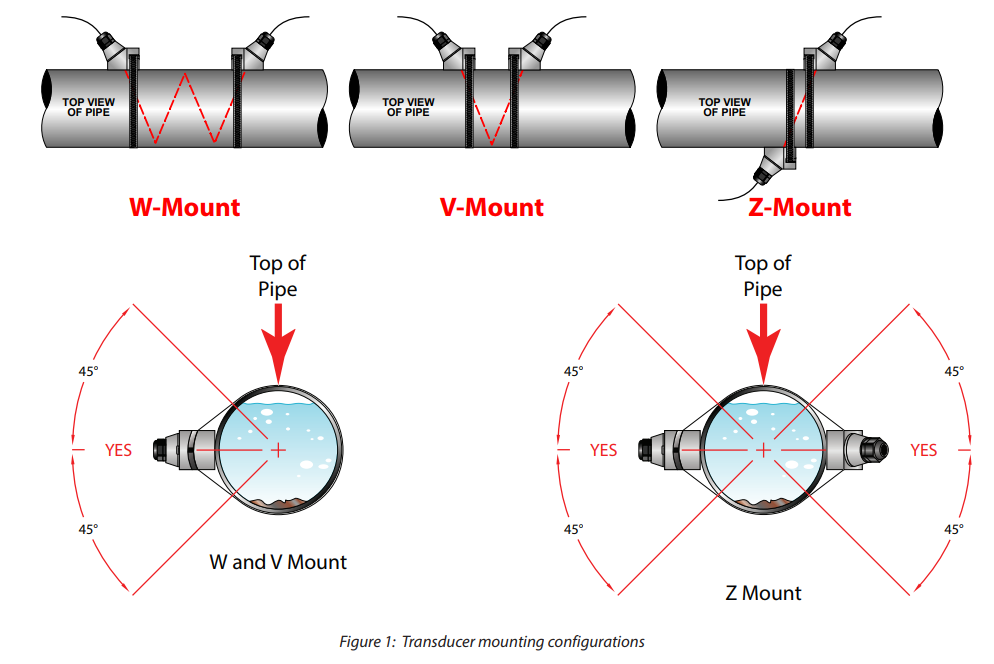

How the flow rate is determined varies depending on the nature of the application. The flow velocity and direction are accurately determined. The transducers should be installed at a pipe section where the length of the straight pipe on the upstream side is at least 10D and on the downstream side is at least 5D.

If the flow meter screen still fails to illuminate the batteries may require replacement. 12 TYPICAL F-4300 FLOW METER INSTALLATION The F-4300 Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on the outside wall of the pipe. The meter is housed in an.

Ultrasonic flowmeters consist of clamp-on transducers that are attached on the outside wall of the pipe with flowing water Figure 1. Here D stands for pipe outer diameter. Integrated wall thickness measurement.

The sensors measure flow by transmitting and receiving ultrasonic signals directly through the pipe wall and the medium. Flexim manufactures a full range of ultrasonic flow measurement equipment and instruments for industrial and commercial applications. Flexim a globally recognized leader in the manufacture of ultrasonic flow meters provides us with a video that steps through the installation process with recommendations and guidance along the way.

Up to 15 cash back Overview. It is suitable for measuring the volumetric flow of liquids in a wide variety of applications including bi-directional flow applications. It is suitable for measuring the volumetric flow of liquids in a wide variety of applications including bi-directional flow applications.

13 TYPICAL F-4000 FLOW METER The F-4000 Series Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on the outside wall of the pipe. Refer to the following table for more details. The meter is housed in a steel.

The ultrasonic flowmeter has a wide range and the flow rate can usually be from 1 ms to 30 ms or a larger flow rate under the condition of ensuring high measurement accuracy. Flexim a globally recognized leader in the m. In future parts we will be discussing installation effects in more detail.

Transit-time is the preferred mode. If the flow meter fails to turn on open the battery compartment remove the batteries check their integrity and replace in the flow meter.

Tuf Clamp On Ultrasonic Flow Meter Apure

Clamp On Ultrasonic Flow Meters Installation Guidelines Rms Engineering

Portable Ultrasonic Flow Meter Installation Tutorial How To Solve No Signal Message Youtube

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

Clamp On Ultrasonic Gas Flow Meters

Si 3403 Clamp On Ultrasonic Flow Meter Sino Inst

Clamp On Ultrasonic Flow Meters Installation Guidelines Rms Engineering

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

Clamp On Transit Time Ultrasonic Flow Meter

Common Mounting Configurations Z Method Top V Method Middle And W Download Scientific Diagram

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

Portable Clamp On Ultrasonic Flow Meter For Water Ato Com

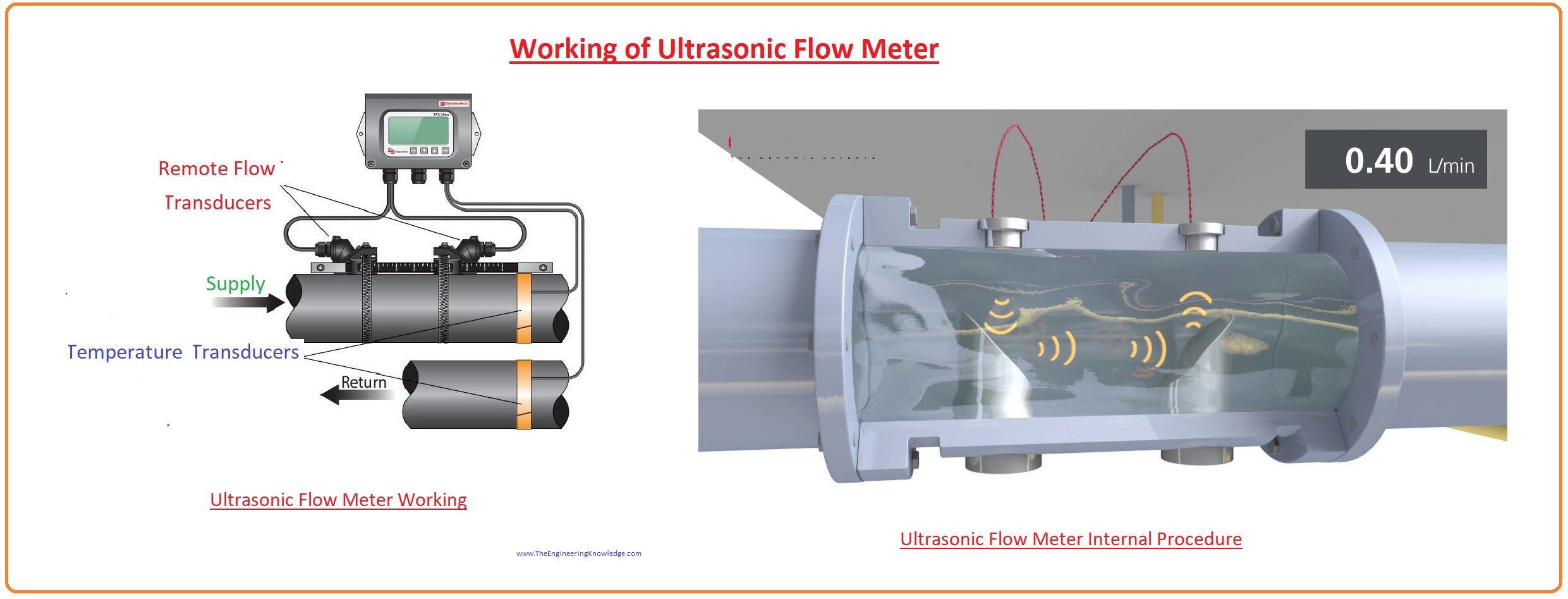

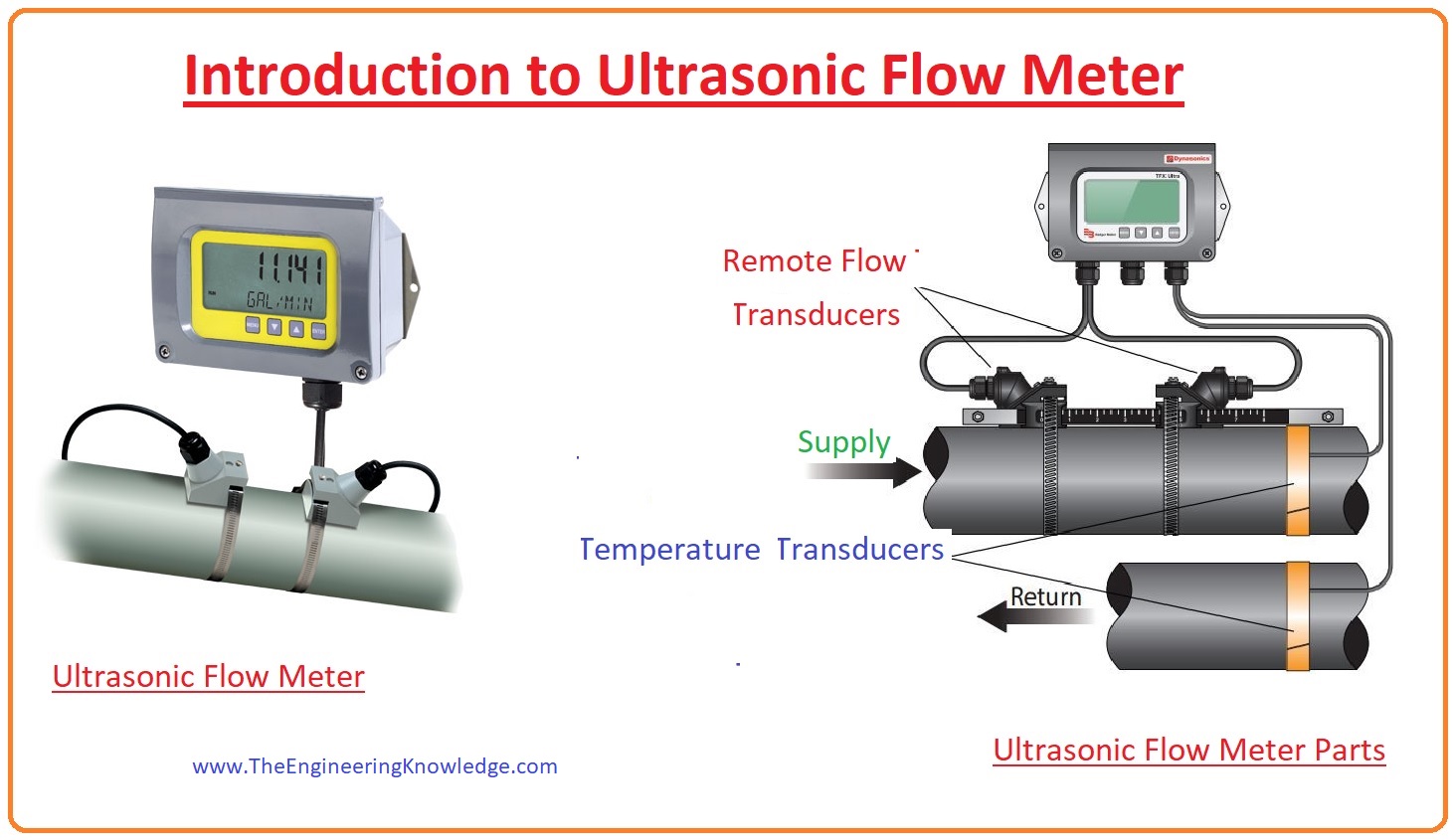

Ultrasonic Flow Meter The Engineering Knowledge

How To Install Clamp On Ultrasonic Flowmeters I Mega Instrument

Ultrasonic Flow Meter The Engineering Knowledge

![]()

F 4300 Clamp On Ultrasonic Flow Meter Thermal Energy Measurement System Onicon Flow And Energy Measurement